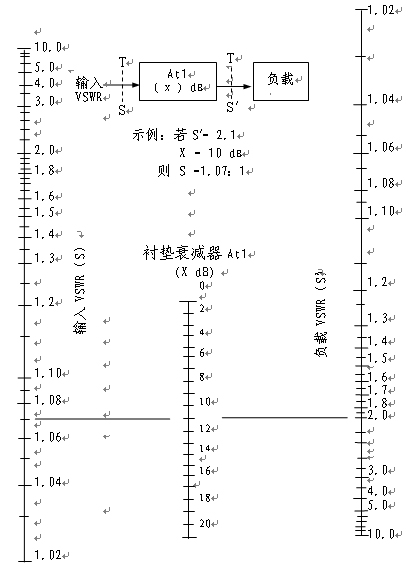

Cushion Attenuator and Its Applications

|

|||||||||||||||||||||||||||||||||||||||||||

NEWS CENTER

Contact Us

Superb Automation Co., Limited

Website:www.superb-tech.com

For 25 years your reliable partner in Electronics & PCBA!

HK number: 85260404363

Email :Info@superb-tech.com

Whatsapp:8613396081443